Wadi Kabir Workshops Parts Labor Warranty Costs: Optimizing Financial Control in Muscat’s SME Sector

Understanding Parts Tracking Challenges in Wadi Kabir Workshops

Identifying the Core Issues

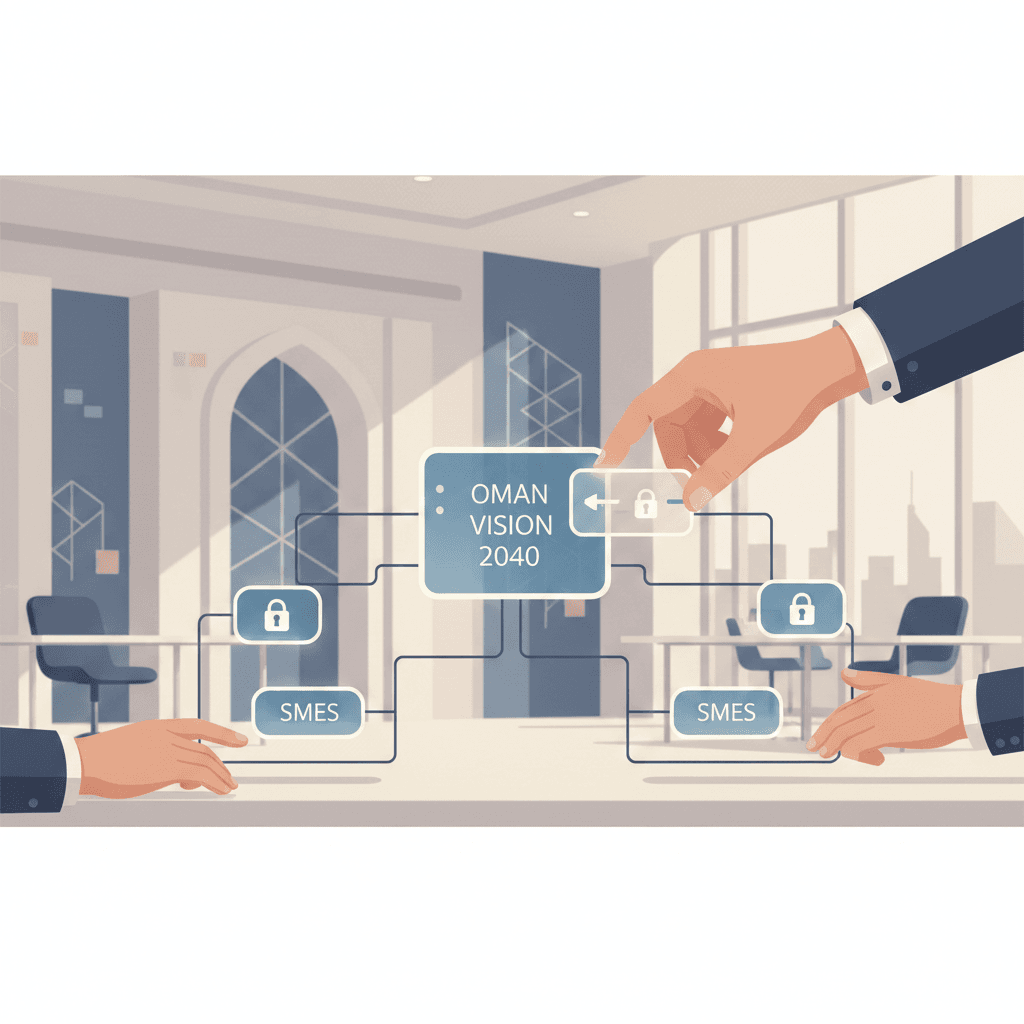

Wadi Kabir workshops parts labor warranty costs tracking presents unique challenges, especially in managing the parts used for repairs and maintenance. For SME owners and finance managers in Muscat, accurately monitoring inventory movements is essential not only for operational efficiency but also for protecting profit margins. Many workshops continue to depend on manual processes or disconnected systems, resulting in discrepancies between recorded and actual parts usage. These gaps can lead to inflated expenses, stock shortages, and an unclear understanding of true repair costs. Identifying the root causes—such as poor record-keeping and lack of integration with financial systems—is crucial to improving parts management. In Oman’s dynamic business environment, workshop owners must implement practical controls aligned with their size and resources to remain competitive.

Effective parts tracking involves establishing clear accountability and using technology where possible. SMEs in Wadi Kabir can benefit from simple yet robust processes that record every part issued against specific jobs. Linking parts consumption directly to labor activities and invoices ensures transparency. This approach helps finance managers reconcile costs monthly and detect anomalies early. Leaderly’s advisory services emphasize this integration as a foundation for better inventory control, reducing waste and fraud risks. Ultimately, aligning parts tracking with overall workshop financial governance improves decision-making and builds trust with customers and suppliers alike.

Integrating parts management with accounting systems also facilitates compliance with Oman’s VAT regulations, ensuring that inputs and outputs are recorded correctly. Given the relatively high cost of spare parts in the region, even small errors can significantly impact the bottom line. Workshops that fail to monitor parts closely risk overstating expenses or losing money on warranty claims. Therefore, a proactive approach to parts tracking is indispensable for SMEs aiming for sustainable growth in Wadi Kabir’s competitive automotive repair market.

Labor Cost Control in Wadi Kabir Workshops

Balancing Efficiency and Accuracy

Labor costs represent a substantial portion of total expenses for Wadi Kabir workshops, making their control essential for profitability. However, many SMEs struggle to accurately allocate labor hours to specific jobs or customers. Without precise labor tracking, workshops may undercharge or fail to identify inefficiencies in workforce utilization. This challenge is compounded when multiple technicians work on different tasks, or when jobs extend beyond initial estimates. For finance managers and business owners in Oman, establishing standardized procedures for recording labor time is vital to align invoicing with actual service delivery.

One effective strategy is to implement digital timesheets or job cards that technicians complete in real time. This method provides transparency and enables managers to monitor labor productivity continuously. Moreover, linking labor costs directly to parts usage and warranty claims offers a complete picture of repair costs. Leaderly’s advisory expertise supports workshops in designing practical labor tracking frameworks that reflect local operating realities, including fluctuating demand and varying skill levels. By controlling labor costs with precision, Wadi Kabir workshops can improve pricing accuracy, boost cash flow, and enhance customer satisfaction through timely service delivery.

Incorporating labor cost control within overall financial governance also aids in compliance with Oman’s labor laws and tax requirements. Proper documentation of hours worked ensures transparency during audits and helps prevent disputes. For SME owners seeking to scale their operations, robust labor cost management builds a foundation for performance-based incentives, driving both productivity and morale. Ultimately, a disciplined approach to labor tracking is a cornerstone of sustainable workshop management in the Muscat region.

Warranty Cost Management: Protecting Profit Margins

Mitigating Risks through Transparent Processes

Warranty costs present a complex challenge for Wadi Kabir workshops. Covering repairs under warranty agreements without clear cost control can erode margins quickly. Many SMEs find it difficult to separate warranty work from billable services, leading to confusion in financial reporting. Moreover, unclear policies on parts replacement and labor allowances under warranty contribute to inconsistent practices and potential losses. For finance managers and business owners in Oman, establishing transparent warranty cost tracking is essential to safeguarding profitability and customer trust.

Effective warranty management requires a systematic process to record all warranty claims, linking them to the original sales or service contracts. Workshops should maintain detailed logs of parts and labor used under warranty, supported by clear authorization workflows. Leaderly’s audit and advisory services highlight the importance of internal controls that reconcile warranty expenses against vendor reimbursements or manufacturer agreements. Such controls help prevent abuse and ensure that warranty costs are accurately reflected in financial statements. For SMEs, managing warranty costs well enhances reputation and provides valuable insights into product reliability and service quality.

Proactive warranty cost tracking also supports cash flow management, as delayed or unclaimed reimbursements can strain working capital. By integrating warranty data with parts and labor tracking, Wadi Kabir workshops can identify recurring issues and negotiate better terms with suppliers. This holistic approach reduces unexpected expenses and helps SMEs remain competitive in Oman’s automotive repair market. In summary, clear and consistent warranty cost management is a strategic priority for sustaining workshop profitability.

Integrating Parts, Labor, and Warranty Costs for Financial Clarity

Building a Unified Cost Management System

Combining parts, labor, and warranty cost tracking into a cohesive system is a critical step for Wadi Kabir workshops seeking operational excellence. Disparate data silos often hinder SMEs from obtaining a full view of job profitability and workshop performance. Integration enables managers and finance teams to monitor job costs in real time, compare estimates against actuals, and make informed pricing decisions. In the Omani context, where market competition is increasing, workshops that master this integration gain a strategic advantage through improved financial clarity.

Leaderly encourages SMEs to adopt digital tools that facilitate seamless data flow between inventory management, timesheets, and warranty records. Even for smaller workshops, affordable solutions exist that scale with business growth. By aligning these cost components, workshops enhance internal controls and reduce errors or omissions. This transparency also builds confidence among business owners, lenders, and investors evaluating the workshop’s financial health. More importantly, integrated cost management supports compliance with Oman’s tax framework by ensuring accurate documentation and reporting of expenses.

Moreover, integration provides actionable insights that help workshops optimize resource allocation and customer service. Identifying cost drivers enables targeted improvements and informs negotiations with suppliers and labor providers. For SME founders and finance managers, this holistic approach delivers a robust foundation for sustainable growth in Muscat’s dynamic repair services market. Ultimately, integrating parts, labor, and warranty cost management transforms financial governance from a reactive task into a strategic asset.

Leveraging Leaderly’s Advisory and Audit Services for Workshop Success

Practical Support Tailored to Wadi Kabir SMEs

Leaderly’s expertise in audit, accounting, taxation, and advisory services offers Wadi Kabir workshops practical guidance tailored to their unique challenges. Understanding that many SMEs operate with limited resources, Leaderly focuses on cost-effective solutions that enhance transparency and compliance without disrupting daily operations. Their advisory approach covers feasibility studies, due diligence, and valuation, helping workshop owners make informed investment and growth decisions. For finance managers, Leaderly’s audit services provide assurance that parts, labor, and warranty costs are correctly captured and reported, mitigating financial risks.

Leaderly also supports workshops in navigating Oman’s corporate tax and VAT regulations, ensuring proper treatment of repair expenses and revenues. This compliance reduces the risk of penalties and enhances cash flow management. By partnering with Leaderly, SMEs gain access to practical tools and expert insights that empower them to optimize cost control and improve profitability. This partnership fosters a culture of disciplined financial governance essential for long-term success in Wadi Kabir’s competitive landscape.

Ultimately, Leaderly’s comprehensive services enable workshops to move beyond basic bookkeeping toward strategic financial management. This progression is critical for SME owners and finance managers aiming to expand their business, improve customer trust, and compete effectively in the Muscat market. With Leaderly’s support, Wadi Kabir workshops can confidently address parts, labor, and warranty cost challenges while positioning themselves for sustainable growth.

Building a Future-Ready Workshop in Wadi Kabir

Embracing Technology and Best Practices

The future of automotive repair workshops in Wadi Kabir hinges on embracing technology and sound financial practices. SMEs that invest in digital parts inventory, labor tracking systems, and warranty management tools stand to gain greater control over costs and operational efficiency. Such investments also facilitate compliance with Oman’s increasingly complex regulatory environment. For business owners and finance managers, adopting these best practices signals a commitment to professionalism and quality service that attracts discerning customers.

Beyond technology, cultivating a culture of accountability among workshop staff is equally important. Clear processes for parts issuance, labor recording, and warranty approvals must be communicated and enforced consistently. Leaderly’s advisory services emphasize training and internal control frameworks tailored to the scale and needs of each SME. This holistic approach not only protects profit margins but also supports scalability and resilience in changing market conditions.

In summary, Wadi Kabir workshops that integrate financial controls with operational improvements position themselves as leaders in Muscat’s automotive sector. By proactively managing parts, labor, and warranty costs, SMEs can unlock new growth opportunities and build sustainable competitive advantages. With expert guidance and a commitment to continuous improvement, the future for Wadi Kabir workshops is promising and full of potential.

#Leaderly #WadiKabirWorkshopsPartsLaborWarrantyCosts #Oman #Muscat #SMEs #Accounting #Tax #Audit